Distribution Center and Warehouse Radiant Heating Solutions

Keep Dock Doors Warm, Keep Employees Happy and Productive

Consistent, Even Heat Throughout the Warehouse

Infrared heating systems are highly effective in a warehouse environment. Our warehouse infrared heating systems are installed over the largest and most open areas in the building for maximum effectiveness, as well as in strategically chosen locations between shelves. Heating these areas with a traditional heating system often results in uneven heating. With a warehouse infrared tube heater from Roberts-Gordon, you’ll have a custom layout that is designed to provide consistent and even heat throughout the entire warehouse.

Keep Dock Door Employees Warm, Even When Overhead Doors Are Open

Dock doors are a critical component in manufacturing plants and storage warehouse buildings. They accept product into and out of the building on a consistent basis. What’s the main problem within this area of the building? Heat loss is unavoidable.

Heat loss is simply the loss of heat from an object or space within a building or area. As shipping/receiving doors open, warm air leaves the building resulting in cold spaces and high heating costs. Traditional warm air unit heaters cannot tackle this problem. The most effective, efficient solution are loading dock infrared tube heaters.

Roberts-Gordon infrared heating systems can be customized to warehouse size, ceiling height, and heat requirements. Regardless of the specific needs of the application, infrared tube heating ensures affordable, consistent heat – no matter the space.

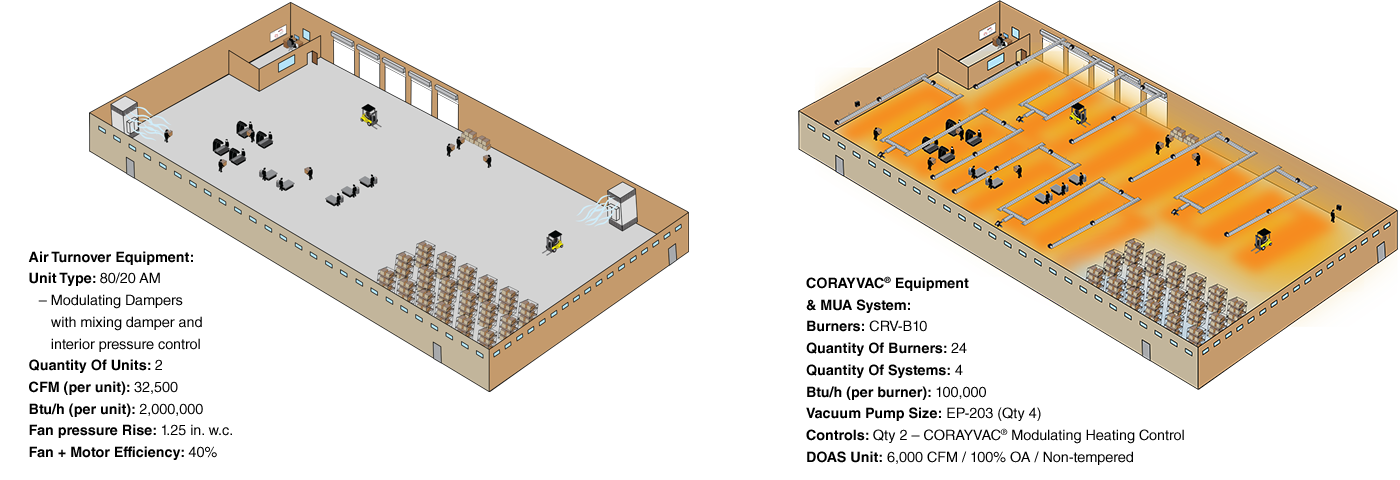

Indirect-Fired Air Turnover Units Versus Infrared Tube Heaters

Traditional heating systems, like air turnover units, often face challenges in applications such as loading docks. These areas pose a unique problem because when overhead doors are opened for loading or unloading, a significant amount of warm air generated by traditional heaters escapes. This causes an immediate temperature drop. This rapid heat loss not only leads to discomfort for employees working in these open areas, but also creates inefficiencies in energy consumption and overall heating effectiveness.

Fortunately, radiant tube heaters offer a superior solution to addressing these issues effectively. Unlike traditional heating systems that heat the air, infrared heaters emit radiant heat. This directly targets and warms people, floors, and objects in their path.

See the vast difference in the radiant heat pattern when comparing air turnover units with infrared tube heaters. In this study, we measured our CORAYVAC® Infrared heating system in comparison with air turnover units. Because the temperature can be set lower to maintain the same comfort level, CORAYVAC® saves 37% in energy costs compared to a traditional heating system.

Air Turnover Units vs Radiant Tube Heating

CORAYVAC® Custom Engineered Radiant Heating System

Each distribution facility differs in terms of size, ceiling height, and the amount of heat needed. With our CORAYVAC® continuous radiant heating system, you have a wide range of fully custom options to suit your requirements.

Building owners need a balanced system that addresses fresh air requirements, reduces waste, enhances efficiency, and provides well-targeted, zoned heating. Roberts-Gordon provides a solution that meets all these needs and more for large, open areas like distribution centers, warehouses and manufacturing.

Get a Free Heat Loss Analysis or Facility Design Today!

Find A Rep Near You!

Many of our independent representative partners are second and third generation firms. These infrared heating experts can help guide you through the entire buying process from design to installation.